When it comes to security screen doors and windows, stainless steel mesh is one of the most commonly used materials for its durability and strength. To ensure that your mesh is up to par, it’s essential to understand the crucial factors that influence mesh quality, such as the material grades and diameters, weaving types, coatings, and industry standards. In this article, we’ll delve into each of these areas to help you make informed decisions when selecting the ideal mesh for your needs.

Material grades:

The choice of material grade does not only determine the corrosion and heat resistance but also the mechanical stability of the woven mesh.

If you reside in a region that is coastal or prone to corrosion, selecting marine grade 316 stainless steel is highly recommended due to its excellent corrosion resistance and durability. If you live in a moderately corrosive environment, opting for 304 stainless steel is an excellent decision, as it offers superior corrosion resistance and strength.

Material diameters:

The diameter of the wire is another vital factor that determines the strength of the mesh. Mesh made from thicker wires (0.8mm/0.032” above) can provide extra resistance against vandalism and heavy impacts. When verifying the wire diameter with your supplier, it is essential to ensure that they are referring to the “wire diameter before powder coating.” It is possible that certain suppliers may apply an excessive amount of powder coating in order to create the illusion of a thicker wire.

| Normal coating – square openings | Excessive coating – round openings |

|   |

Weave Types:

Security screen mesh is a wire cloth that is manufactured on automated looms. There are two primary types of weave used in security screens: plain weave and crimp mesh. Fasolid only utilizes plain weave mesh due to its precise opening and high-tensile strength achieved by weaving warp wires and weft wires over and under each individual wire strand in both directions. On the other hand, crimp mesh involves pre-crimping the wire mesh before the final weaving process. This pre-crimping process renders the mesh more brittle and less capable of absorbing impact.

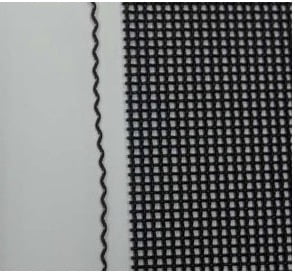

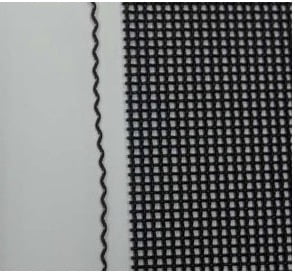

| Plain Weave | Pre-crimp |

|   |

Coatings:

The coating or finish applied to the stainless steel mesh can enhance its durability and resistance to corrosion. Look for options with a powder-coated finish, as they provide better protection against rust and corrosion. Fasolid uses the world-leading akzo powder because it delivers a resilient and superior finish that endures the test of time, resulting in cost savings and peace of mind. Powder coating is also an environmentally friendly process, as the coatings contain no solvents and do not release volatile organic compounds (VOC) into the atmosphere.

Standards Compliance:

Compliance with industry standards is essential for ensuring that the mesh you select is safe and reliable. ISO and ASTM standards provide specific guidelines and procedures for testing the mesh’s strength, durability, and resistance to various hazards such as weathering and corrosion. At Fasolid, we manufacture all our mesh products to comply with ASTM E2016-06 to provide our customers with tested and reliable quality.

When selecting stainless steel mesh for security screen doors and windows, it’s important to consider a professional supplier with expertise in mesh manufacturing. The factors we discussed, such as material grades and diameters, weave types, coatings, and standards compliance, all play a crucial role in determining the quality and durability of the mesh. By understanding these factors, you’ll be able to make informed decisions and choose the right product for your needs. At Fasolid, we’re committed to delivering high-quality stainless steel mesh and exceptional customer service. If you have any questions or need assistance, feel free to contact us!